By using this motor remote control kit, you can remote control DC motor. Working modes include toggle, momentary and latching. Easy to wire and operate.The motor remote control kit is suitable for the motors of rolling blinds / doors, projection screens, awnings, pumps, winches, conveyors or other appliances and machines. Remote control distance is up to 1000M

Here is a video about how to use this wireless switch to open or close a valve.

https://www.youtube.com/watch?v=Njnr08DT0fY

Here is a video about how to use this wireless switch to remotely control a DC motor.

https://www.youtube.com/watch?v=mvWHDVpIi4g

Package Include:

1 x Receiver: S1FU-DC06 / S1FU-DC09 / S1FU-DC12 / S1FU-DC24

2 x Transmitter: C-3-2

1 x User manual

Feature:

Wireless control, easy to install

Control motors of rolling blinds / doors, projection screens, awnings, pumps, winches, conveyors or other appliances and mechanicals with DC voltage.

You can turn on/off the receiver with transmitter (remote control) from any place within a reliable distance; the wireless signal can pass through walls, floors and doors.

With characteristics of reverse power protection and over current protection

Audible / visual indication

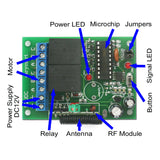

Use microcontroller model of EM78P156, an 8-bit microprocessor designed and developed with low-power and high-speed CMOS technology.

Reliable control: The transmitter (Encoding) and the receiver (Decoding) use an 8-bit code.

One/several transmitters can control one/several receivers simultaneously.

If you use two or more receivers in the same place, you can set them with different codes.

Transmitting Frequency: 433MHz

Receiver:

Model No: S1FU-DC06 / S1FU-DC09 / S1FU-DC12 / S1FU-DC24

Control Modes: Inversion (Self-locking, Momentary, Interlocking)

Coding Type: Fixed code

Coding Setting: By learning

Power Supply (Operating Voltage): DC6V (S1FU-DC06), DC9V±1V (S1FU-DC09), DC12V±1V (S1FU-DC12), DC24V±1V (S1FU-DC24)

Output: DC6V (S1FU-DC06), DC9V (S1FU-DC09), DC12V (S1FU-DC12), DC24V (S1FU-DC24)

PCB size: 67mm x 50mm x 18mm

Case size: 75mm x 54mm x 27mm

Static Current: ≤6mA

Maximum Working Current: 10A

Transmitter:

Model No.: C-3-2

Channel: 3 CH

Remote Control Distance: 100m / 300ft (theoretically)

Encode: Fixed code by bonding pad encoded

Unit size: 58mm x 39mm x 16mm

Power Supply: 1 x 23A -12V battery (included, can be used for 12 months)

Usage:

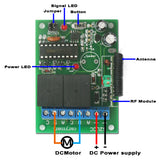

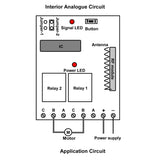

Connect the motor to Terminal B of relay 1 and relay 2.

Setting different control modes (We have set the receiver as Self-locking control mode before delivery. If you want to use other control modes, do as following operation):

Setting control mode Self-locking: Only connect Jumper-2.

Control mode Self-locking: Press -> Rotate; Press again -> Stop.

Press button ▲: Terminal B of relay 1 and relay 2 output + DC (1: +, 2: -), motor rotates in the positive direction.

Press button ▲ again: Terminal B of relay 1 and relay 2 no output, motor stops

Press button ▼: Terminal B of relay 1 and relay 2 output - DC (1: -, 2: +), motor rotates in the reversal direction.

Press button ▼ again: Terminal B of relay 1 and relay 2 no output, motor stops

Setting control mode Momentary: Only connect Jumper-1.

Control mode Momentary: Press and hold -> Rotate; Release -> Stop.

Press and hold button ▲: Terminal B of relay 1 and relay 2 output + DC (1: +, 2: -), motor rotates in the positive direction.

Release button ▲: Terminal B of relay 1 and relay 2 no output, motor stops

Press and hold button ▼: Terminal B of relay 1 and relay 2 output - DC (1: -, 2: +), motor rotates in the reversal direction.

Release button ▼: Terminal B of relay 1 and relay 2 no output, motor stops

Setting control mode Interlocking: Do not connect Jumper-1 and Jumper-2.

Control mode Interlocking: Press button ▲ and ▼ -> Rotate; Press button ■ -> Stop.

Press button ▲: Terminal B of relay 1 and relay 2 output + DC (1: +, 2: -), motor rotates in the positive direction.

Press button ▼: Terminal B of relay 1 and relay 2 output - DC (1: -, 2: +), motor rotates in the reversal direction.

Press button ■: Terminal B of relay 1 and relay 2 no output, motor stops

Here is a video about how to use this wireless switch to open or close a valve.

https://www.youtube.com/watch?v=Njnr08DT0fY

Here is a video about how to use this wireless switch to remotely control a DC motor.

https://www.youtube.com/watch?v=mvWHDVpIi4g

Package Include:

1 x Receiver: S1FU-DC06 / S1FU-DC09 / S1FU-DC12 / S1FU-DC24

2 x Transmitter: C-3-2

1 x User manual

Feature:

Wireless control, easy to install

Control motors of rolling blinds / doors, projection screens, awnings, pumps, winches, conveyors or other appliances and mechanicals with DC voltage.

You can turn on/off the receiver with transmitter (remote control) from any place within a reliable distance; the wireless signal can pass through walls, floors and doors.

With characteristics of reverse power protection and over current protection

Audible / visual indication

Use microcontroller model of EM78P156, an 8-bit microprocessor designed and developed with low-power and high-speed CMOS technology.

Reliable control: The transmitter (Encoding) and the receiver (Decoding) use an 8-bit code.

One/several transmitters can control one/several receivers simultaneously.

If you use two or more receivers in the same place, you can set them with different codes.

Transmitting Frequency: 433MHz

Receiver:

Model No: S1FU-DC06 / S1FU-DC09 / S1FU-DC12 / S1FU-DC24

Control Modes: Inversion (Self-locking, Momentary, Interlocking)

Coding Type: Fixed code

Coding Setting: By learning

Power Supply (Operating Voltage): DC6V (S1FU-DC06), DC9V±1V (S1FU-DC09), DC12V±1V (S1FU-DC12), DC24V±1V (S1FU-DC24)

Output: DC6V (S1FU-DC06), DC9V (S1FU-DC09), DC12V (S1FU-DC12), DC24V (S1FU-DC24)

PCB size: 67mm x 50mm x 18mm

Case size: 75mm x 54mm x 27mm

Static Current: ≤6mA

Maximum Working Current: 10A

Transmitter:

Model No.: C-3-2

Channel: 3 CH

Remote Control Distance: 100m / 300ft (theoretically)

Encode: Fixed code by bonding pad encoded

Unit size: 58mm x 39mm x 16mm

Power Supply: 1 x 23A -12V battery (included, can be used for 12 months)

Usage:

Connect the motor to Terminal B of relay 1 and relay 2.

Setting different control modes (We have set the receiver as Self-locking control mode before delivery. If you want to use other control modes, do as following operation):

Setting control mode Self-locking: Only connect Jumper-2.

Control mode Self-locking: Press -> Rotate; Press again -> Stop.

Press button ▲: Terminal B of relay 1 and relay 2 output + DC (1: +, 2: -), motor rotates in the positive direction.

Press button ▲ again: Terminal B of relay 1 and relay 2 no output, motor stops

Press button ▼: Terminal B of relay 1 and relay 2 output - DC (1: -, 2: +), motor rotates in the reversal direction.

Press button ▼ again: Terminal B of relay 1 and relay 2 no output, motor stops

Setting control mode Momentary: Only connect Jumper-1.

Control mode Momentary: Press and hold -> Rotate; Release -> Stop.

Press and hold button ▲: Terminal B of relay 1 and relay 2 output + DC (1: +, 2: -), motor rotates in the positive direction.

Release button ▲: Terminal B of relay 1 and relay 2 no output, motor stops

Press and hold button ▼: Terminal B of relay 1 and relay 2 output - DC (1: -, 2: +), motor rotates in the reversal direction.

Release button ▼: Terminal B of relay 1 and relay 2 no output, motor stops

Setting control mode Interlocking: Do not connect Jumper-1 and Jumper-2.

Control mode Interlocking: Press button ▲ and ▼ -> Rotate; Press button ■ -> Stop.

Press button ▲: Terminal B of relay 1 and relay 2 output + DC (1: +, 2: -), motor rotates in the positive direction.

Press button ▼: Terminal B of relay 1 and relay 2 output - DC (1: -, 2: +), motor rotates in the reversal direction.

Press button ■: Terminal B of relay 1 and relay 2 no output, motor stops